Home > Company Introduction

Company Overview

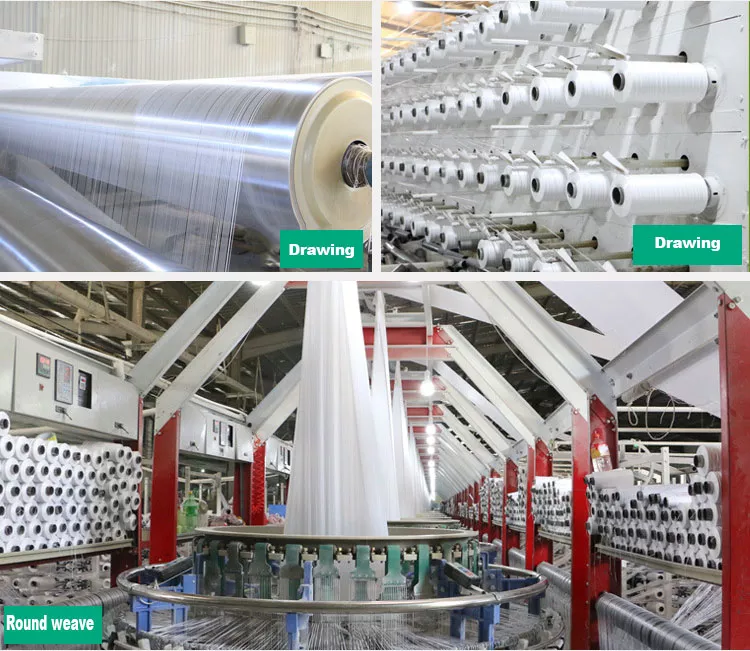

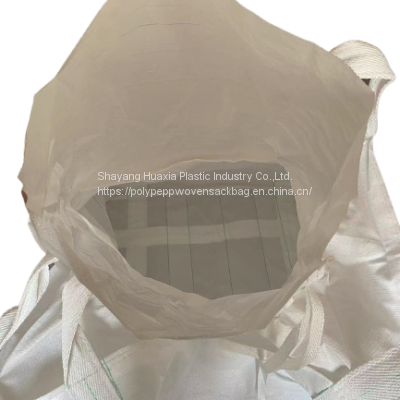

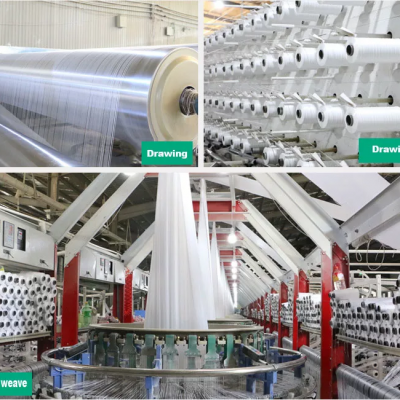

We occupy a total of 16,000 square meters of land, around 500 employees working together. And our yearly production capacity is around 50,000MT.We possess a series of advanced Starlinger equipment including extruding, weaving, coating, laminating, and bag produce. It was worth mentioning that, we are the first manufacturer in domestic that imports the AD* STAR equipment in the year 2009. With the support of 8 sets of ad starKON , our annual out put for AD Star bag exceeds 300 million.Besides the AD Star bags, BOPP bags, Jumbo bags, as traditional packaging options, are also in our main product lines.Certification: ISO9001,BRC, Labordata, RoHS.H – High-quality, 100% virgin PP material. 15 control points and 5 critical control stage, piece by piece inspection before shipment.A – Advanced equipment: Starlinger is the top brand equipment of pp woven bags producing.P – Professional: With three generations of engagement in this industry, Rich experience, ingenuity, always pay attention to the development of the industry, focus on details, which made us have a wealth of professional knowledge and solutions.P – Passion: Things will be different and meaningful because of passion, the great love for this industry, has kept us on the right path and headed on.Y – Yes: We also take it as “Empathy”, to know what our client's concern about, to do what we can with what we have to support.Sales Manager:DanielMobile Phone:86- 13802155833E-mail:tjwhoking@163.comQQ:490045876SKYPE:antonio87455WeChat:13802155833WhatsApp: 86-13802155833

-

ManufacturerBusiness Type

-

2003Year Established

-

10,000-30,000 square metersFactory Size

-

US$10 Million - US$50 MillionAnnual Export Value

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

201 - 300 People Total Employees

-

1-10 People Sales Staff

-

10-20 People Quality Inspectors

-

HACCP, TL900, QS9000, SA8000, ISO9001, ISO9004, ISO17799, ISO9000, ISO14000, ISO10441, ISO16949, TS16969, ISO19011:2000, OHSAS18001, Others Product Certifications

-

US$10 Million - US$50 Million Annual Export Value

-

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market Main Markets

-

Tianjin, Qingdao, Shanghai, Ningbo Port of Shipment

-

Woven Bag Main Industry

-

Our ServicesPP Woven Sack;PP Woven Sack with Liner;Rice PP Woven Sack;Flour PP Woven Sack;Corn PP Woven Sack; Vegetable PP Woven Sack;Sugar PP Woven Sack;Salt PP Woven Sack;Feed PP Woven Sack;Fertilizer PP Woven Sack; Sand Woven Sack;Cement Woven Sack;Mineral PP Woven Sack;Resin PP Woven Sack;Polymer PP Woven Sack; Granules PP Woven Sack;Perforated Sacks;Box Sacks;Gusseted Sacks;Transparent PP Woven Sack;Mail PP Woven Sack;PP Shopping Sack;Leno Sacks;Paper Sack;BOPP Outside Coated Sacks;Chemical PP Woven Sack;PP Beach Mat Circular Woven Fabric;Wide Round-Woven Fabric;Flat Woven Fabrics;FIBC Fabric and Sacks;PP Woven Sack OEM

Our ServicesPP Woven Sack;PP Woven Sack with Liner;Rice PP Woven Sack;Flour PP Woven Sack;Corn PP Woven Sack; Vegetable PP Woven Sack;Sugar PP Woven Sack;Salt PP Woven Sack;Feed PP Woven Sack;Fertilizer PP Woven Sack; Sand Woven Sack;Cement Woven Sack;Mineral PP Woven Sack;Resin PP Woven Sack;Polymer PP Woven Sack; Granules PP Woven Sack;Perforated Sacks;Box Sacks;Gusseted Sacks;Transparent PP Woven Sack;Mail PP Woven Sack;PP Shopping Sack;Leno Sacks;Paper Sack;BOPP Outside Coated Sacks;Chemical PP Woven Sack;PP Beach Mat Circular Woven Fabric;Wide Round-Woven Fabric;Flat Woven Fabrics;FIBC Fabric and Sacks;PP Woven Sack OEM -

Company History• 1. Factory produce factory export. 2. Engaged in this industry since 2002, with more than 20 years of experience 3. Top-grade equipment has been introduced since 2009 to ensure higher quality and reduce the overall cost for customers. 4. Occupied a total of 160,000m2 of production area and can make sure an annual output of more than 500 million bags. 5. Professional design team, well-cooperated cylinder workshop, with sufficient experience in handling more than 6,000 kinds of bags, to meet the unique needs of customers • 6. Good reputation, we aim at a long and stable relationship with our valuable customers. 7. Professional Services *pre-sale service

Company History• 1. Factory produce factory export. 2. Engaged in this industry since 2002, with more than 20 years of experience 3. Top-grade equipment has been introduced since 2009 to ensure higher quality and reduce the overall cost for customers. 4. Occupied a total of 160,000m2 of production area and can make sure an annual output of more than 500 million bags. 5. Professional design team, well-cooperated cylinder workshop, with sufficient experience in handling more than 6,000 kinds of bags, to meet the unique needs of customers • 6. Good reputation, we aim at a long and stable relationship with our valuable customers. 7. Professional Services *pre-sale service -

Our Team• Production process of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack: • The following is the whole process to making the Ad*Starkon block bottom valve sack: • Extruding PP particle---------Drawing and cutting PP film-------thread the PP tapes-------Weaving pp tapes to tubular fabric-------Coated with PE film- offset or flexo Printing the body-------hot air welding the tubular body and bottom and top patches and valve--------Inspecting the strength tensile and air permeability-package • Advantage of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack: • Compared with the traditional 3-ply multi-wall paper cement bag and ordinary pp woven plastic bag, the Ad*Starkon block bottom valve sacks have the following advantages: • 1. Economical- lower sack weight save raw material as against the paper bag and PE bags. • 2. Cleaner environment - There is no glue adhesive during the whole production process. • 3. Less risk of damage - high strength tensile pp woven and high speed filling. • 4. Easy handling-the brick shape box shape is easy to palletizing. • Quality control of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack: • In order to produce the high quality Ad*Starkon block bottom valve bags, the following is our effort to control quality: • 1. From material: using 100% original high strength pp material. not recycled or wasted pp material. • 2. For fabric: control the strength tensile and density of pp tapes to satisfy the loading capacity. • 3. Inspection: using the machines to test the strength tensile and tearing function after finish the goods. • 4.Drop test: for safe factor, for each batch of products, will test the air permeability. • Packaging & Shipping

Our Team• Production process of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack: • The following is the whole process to making the Ad*Starkon block bottom valve sack: • Extruding PP particle---------Drawing and cutting PP film-------thread the PP tapes-------Weaving pp tapes to tubular fabric-------Coated with PE film- offset or flexo Printing the body-------hot air welding the tubular body and bottom and top patches and valve--------Inspecting the strength tensile and air permeability-package • Advantage of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack: • Compared with the traditional 3-ply multi-wall paper cement bag and ordinary pp woven plastic bag, the Ad*Starkon block bottom valve sacks have the following advantages: • 1. Economical- lower sack weight save raw material as against the paper bag and PE bags. • 2. Cleaner environment - There is no glue adhesive during the whole production process. • 3. Less risk of damage - high strength tensile pp woven and high speed filling. • 4. Easy handling-the brick shape box shape is easy to palletizing. • Quality control of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack: • In order to produce the high quality Ad*Starkon block bottom valve bags, the following is our effort to control quality: • 1. From material: using 100% original high strength pp material. not recycled or wasted pp material. • 2. For fabric: control the strength tensile and density of pp tapes to satisfy the loading capacity. • 3. Inspection: using the machines to test the strength tensile and tearing function after finish the goods. • 4.Drop test: for safe factor, for each batch of products, will test the air permeability. • Packaging & Shipping